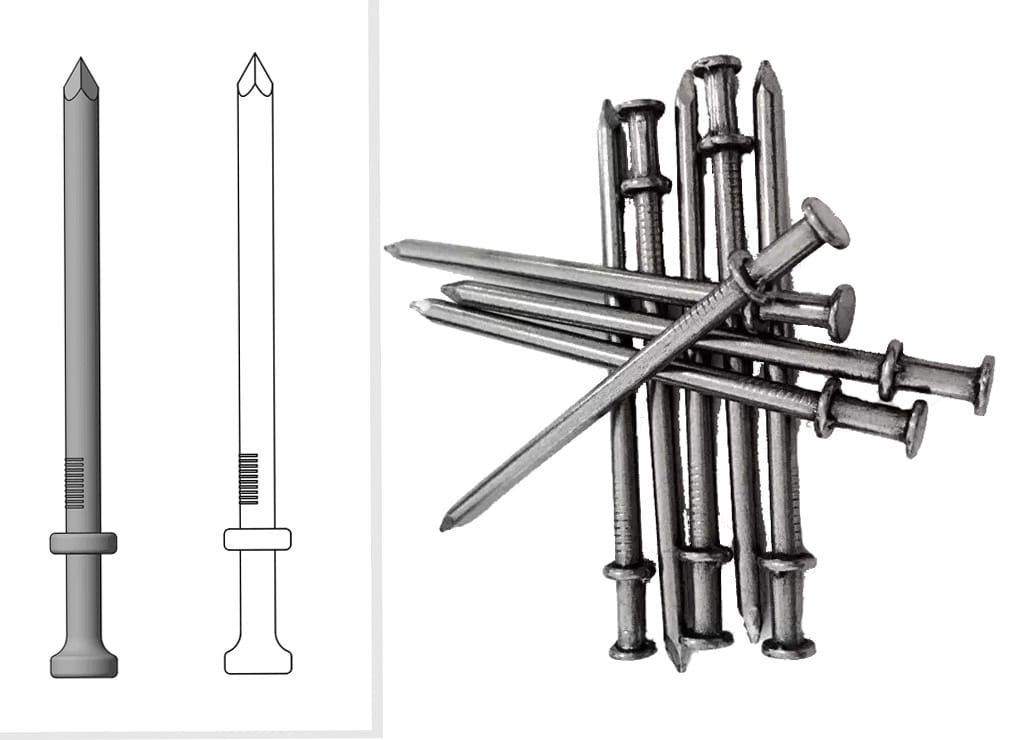

For all the nails, they are consists of hail head, nail body and the nail tip. There are plenty much nail types for different applications, how to choose the right nails for your use? What’s the nail type you need for your project? The Length, diameter, galvanized or not, please read the following content then you will know which type you need.

Nail Types And Their Application In 2022

Table of Contents

Wire Nails

A wire nail is a circular or oval-sectioned head nail made of steel wire. You can use common low carbon steel wire SAE1006-SAE 1030 or galvanized wire to make a wire nail.

Uniwin Nail Manufacturing Machine make wire coils into wire nails by drawing them through wire drawing machine. In the mid-nineteenth century, they were popular as a nail-cutting replacement. Much woodwork is done with wire nails. Wire nails are primarily used for work that is very rough and heavy-duty.

Corrosion resistance, grip strength, and aesthetic appeal can be improved by plating or coating its surface.

Wire nails have a wide range of applications, both domestically and commercially. Even though nails are widely utilized in the construction industry, they also provide an essential contribution to the carpentry trade and the packaging of boxes, among other things. You can use an ordinary wire nail to fasten practically any type of material in almost any situation, from securing hardwood floors to performing routine construction tasks.

Coil Nails

Nail Gun loaded with coil nails have nails placed in a circle joined by a welding wire. Roofing is common for them because they can carry enough nails to finish a roof without reloading. Using two thin welding wires bonded to the nail shanks, coil nails have an adjustable canister that holds a coil of nails – up to 200 framing nails or 300 sheathing nails – at a 15-degree angle. Between reloads, these tools can discharge many nails. Flat and Domed/conical are the two most common types of coil nails.

You can use coil nails in various applications, including the manufacturing of wooden packaging boxes, wooden pallets, wooden furniture, and wooden frame house fences. Coil nails are commonly used to manufacture of wooden pallets and containers and floor boards and other wooden structures requiring great strength. When it comes to high-volume operation, our coil nails are the best choice. Because coils hold vast nails, you may keep reloading downtime to a bare minimum.

The raw material for making coil nails is also SAE1008.

Roofing Nails

Roofing nails are nails used in the installation of roofing materials. Roofing nails come in three shapes: square cap, ring shank, and smooth shank. A ring shank nail is another name for an annular or corrugated roofing nail. A series of rings adorn the shank of this type of nail. The shank of this sort of nail is adorned with a series of rings. None of them are screwed together. It doesn’t matter if these rings help the nail hold on to the sheathing and shingles in any way.

A square cap nail has a square-shaped head rather than the more typical circular head seen on normal nails, It is possible to smooth or curly the square cap nail’s shank. However, the shank is the part of a nail that penetrates material when it is nailed into something. You can buy nails with a smooth shank for less than the other two types of roofing nails, which are more expensive.

It is possible to keep wood and roofing tiles in place with the help of twist shanks and sharp ends. Our nails are made of carbon steel, stainless steel, which are resistant to corrosion and adverse weather. We also offer rubber or plastic washers to prevent water from leaking. Because of their low cost and high performance, these nails with smooth or twisted shanks, and umbrella heads are the most widely used type of nails globally. In addition to providing an aesthetic and ornamental appearance, the umbrella head is intended to prevent roofing sheets from pulling away from the nail’s head.

Double Head Nails

Double-headed nail that we make from steel wire that is brightly finished and have round smooth shanks with flat heads and a diamond tip, as well as have a smooth round shank and a diamond point. What makes double head nails so special is that they have two heads. They are meant to be easily withdrawn means that they do not entirely penetrate the wood during installation.

The use of a double-headed nail, also known as a duplex head nail, in construction scaffolding, form work, and temporary supports can be advantageous. These nails are just like regular nails in terms of strength and ease of removal, except they feature two heads instead of one. It is necessary to drive only the first head of a nail into the wood, leaving a small bit of it and the second head and a little part of the nail visible. All you need is the claw hammer’s reverse end. They are used for short-term projects because a regular nail can easily be used to remove them.

In concrete pouring operations, double-headed nails are used to fasten wood forms in place while the concrete is being poured. the wood forms may be readily dismantled with a hammer and nails that are pulled out by the second head of each nail on either side. The double-headed nails from wooden scaffolding projects are recycled in the same way.

U Nails

U nails is a two-pronged shank fastener with excellent bending resistance and staying power. These nails are frequently employed in the construction of fences.

To build animal coops, you can use them to build a perimeter fence, The name fencing staples comes from these U-shaped nails are typically used to secure mesh fences to timber posts and frames.

For diverse applications, nail shanks come in smooth and barbed versions. Our u nails are commonly used by builders, gardeners, and landscapers to set the perimeters of the farm, for dog kennels with welded mesh fences, and poultry cages and pens can benefit from chicken wire netting.

Garden netting is ideal for protecting plants and harvests. They are easy to use because the slice has a sharp edge.

Concrete Nails

We use #45 or 60 high carbon steel wire that has been hardened to make concrete nails that are strong and durable. They have fluted shafts that help them sink into the concrete. These are also called Steel Nails. Your woodworking projects will last a long time, thanks to the professional finish provided by concrete nails.

The shank of a nail is its cylindrical section. The spherical shape of a concrete nail’s head provides a firm mechanical stop and a surface for striking the nail into the material with a hammer. Because of the ribbed shanks, the nail is less likely to come out of the concrete as time goes on. With a nail driver, you may pound concrete nails into the surface with strong force, making this method the most popular. These are constructed from premium carbon steel and zinc-plated for maximum strength and corrosion resistance.

The instrument uses a forceful pounding action along the nail’s axis to drive the nail deeply into the concrete.

T Nails

T-Nails are versatile and may be used for a variety of purposes, including nailing plywood to concrete, light gauge steel drywall track to concrete, wire lath to masonry, steel banding to wood, wood to steel, decking, fence, sub flooring, and general construction.

Wood Screw Nails

Wood screw nails are usually Phosphating or color galvanized, They are also known as screw shank nails or spiral shank nails due to their unusual configuration. To link two or more relatively thin work pieces or prefabricated components together, wood screw nails are thin metallic fasteners (joining elements) that are driven into and/or screwed into the work piece or prefabricated part.

To fasten metal to hardwood pieces and furniture, such as screws or nails used in wood screw nails are most commonly utilized. Thus, it is possible to replace the structural parts by loosening them. As a fastener/joining element, nails are frequently employed to link many pieces of work or prefabricated parts.

Dry Wall Screw Nails

Drywall screw can also be taken as hardened wooden screw, which can make sure it can be used for hard drywall or steel plate etc. Due to the coarse thread on dry wall screw nails, they are suited for woodworking operations. To hold down large sheets of drywall (usually 4-foot by 8-foot) and smaller sheets of drywall, drywall screws are designed with extremely sharp tips and threads. Because of the nail-pop problem, drywall screws have largely supplanted drywall nails as the primary attachment method for drywall to studs. When it comes to light building projects, you can use drywall screws. They can also be used when safety isn’t an issue.

A drywall bit and electric screwdriver are recommended for optimal results while installing drywall screws.