What is the difference between wire nails and coil nails?

Ordinary wire nails (made from steel wire by wire nail making machine)and coil nails (made from wire nails by thread rolling machine and coil nail collator) have different uses and usages, What are their common features and differences?

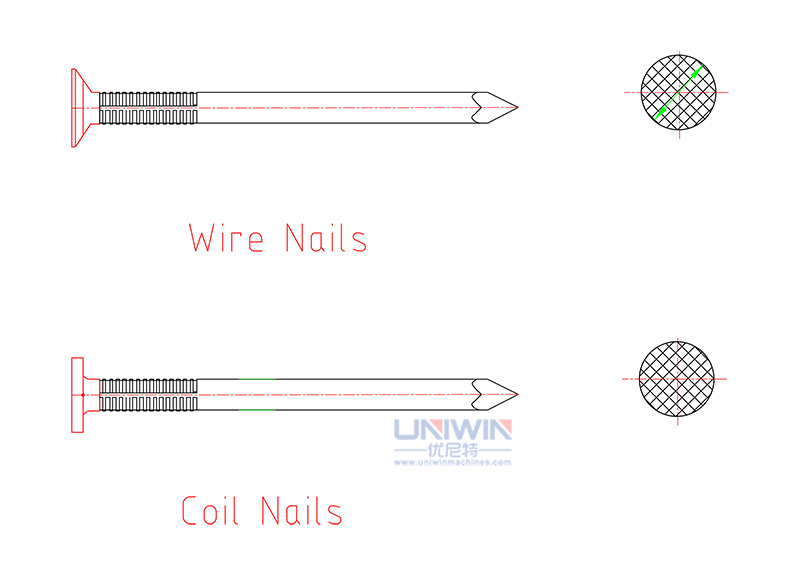

In terms of appearance:

the common feature is that wire nails and coil nails look basically the same, they all have a round nailhead, a diamond nail tip, and a nail shank part. However, there are also some small differences:

- The lower part of the nail head: the lower part of the wire nailhead, is generally tapered, however, the lower part of the coil nail head is flat.

- The thickness and size of the nail cap: the wire nail head thickness is generally thicker, however, the coil nail head is generally thinner and bigger compared with its diameter.

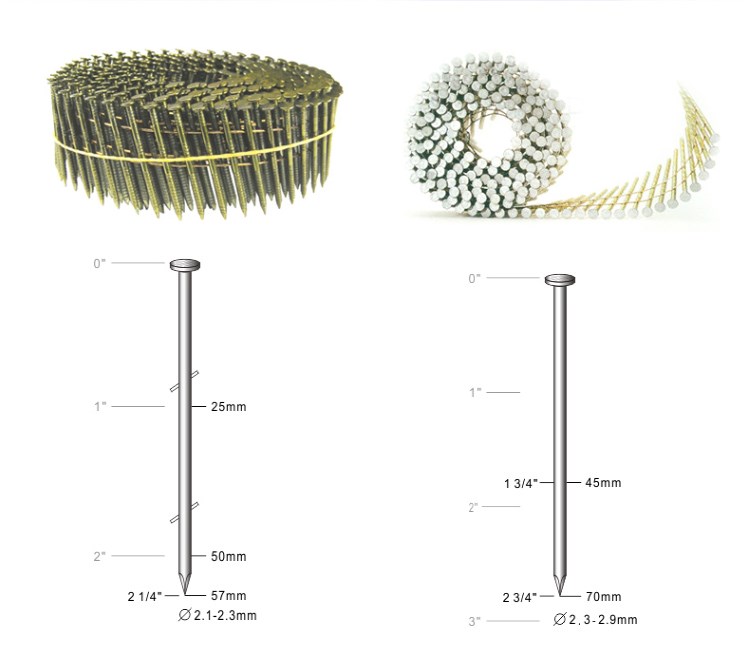

- Nail shank: Round wire nails are generally smooth shanks, However for coil nails, It is usually threaded or ring-shaped shank, so that the nails are not easy to slip out. Some coiled nails are also smooth shank.

In terms of usage and usage:

Wire Nails are typically driven into the workpiece by a hammer, mostly used for rough carpentry or heavy-duty woodwork, the efficiency is low.

Coil Nails are typically driven into the workpiece by a pneumatic nail gun, which can greatly increase efficiency. In a minute, the nail gun can punch 60 pcs nails into wood, however, for wire nails by hammer, can only punch max 2 or 3 nails.

Coil nails are widely used in pallet manufacturing, wooden box manufacturing, cable shafts, and home decoration.

In terms of the material:

Both wire nails and coil nails are made of low carbon steel wire, SAE 1008 or Q195.

In terms of manufacturing:

When making nails with a nail-making machine, for wire nails and coil nails, you need to use the different nail die for each of them.